Tray Loading Systems

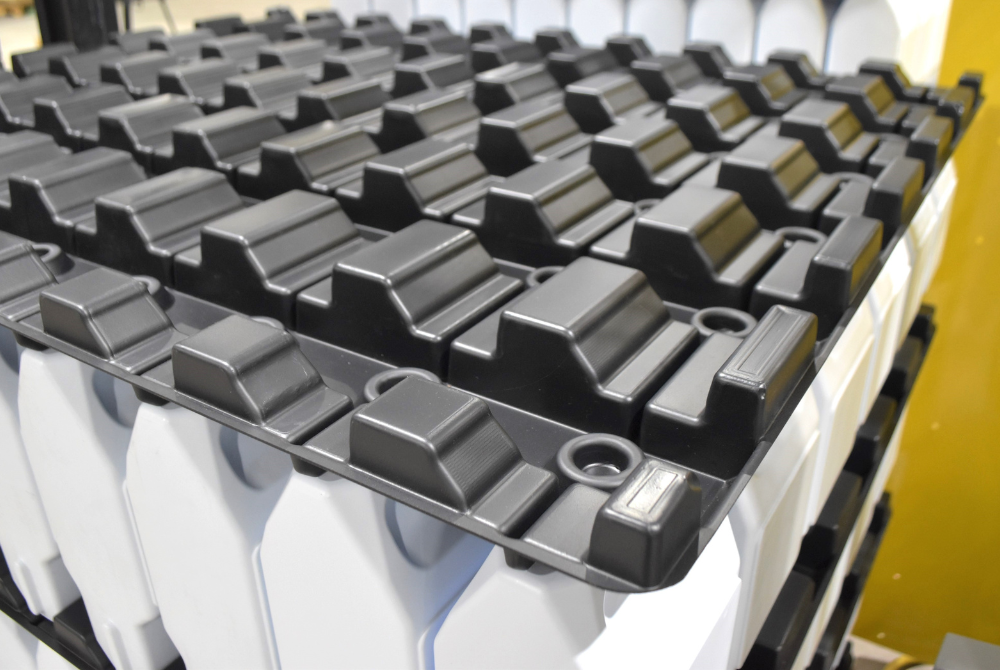

Automatic Tray Loading for Molded Trays

Dyco’s Tray Loading system for molded trays is fully automatic, delivering efficient and rapid loading of diverse bottle-and-tray combinations in one streamlined system. Our quick-change end-of-arm tooling ensures adaptability to various molded tray configurations and sizes.

- Available with bottle inversion options

- Decrease labor costs and increase throughput as compared to manual tray loading

- Change products from the simple-to-use, recipe-driven HMI interface

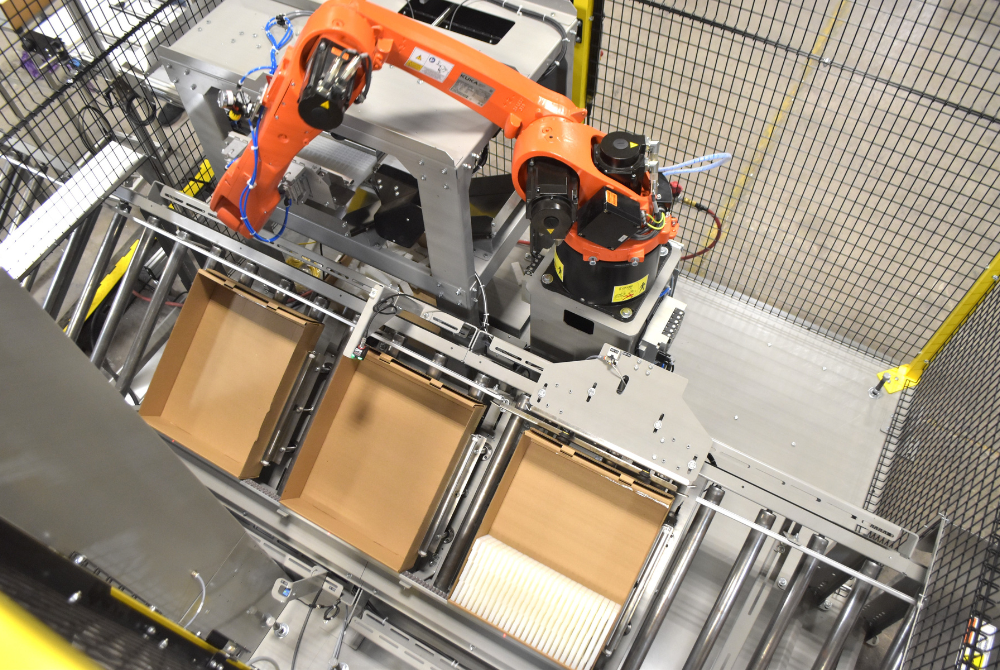

Automatic Tray Loading

Automate the labor intensive parts of your operation with Dyco’s Automatic Tray Loading system – compatible with both fold flat and tab lock trays. The quick change, end-of-arm tooling and easy-to-use HMI interface makes our solution highly adaptable for many different bottle and tray configurations. The tray loader tightly nests bottles to reach the maximum bottles-per-tray capacity.

- Fenceless or collaborative options available

- No robot training required to changeover products, recover from E-stops, or reset the system

- Can be built on a single base for a straight-forward installation or relocation

Semi-Automatic Tray Loading

Dyco’s Semi-Automatic Tray Loading system, compatible with tab lock trays, automates the labor intensive parts of your operation. Bottles enter the packer from a table top conveyor infeed and the packer then forms the containers into rows and, finally, into an array. The array is then pushed directly onto a tray to make the tray ready for shipment.

- Can be built on a single base for a straight-forward installation or relocation

- Gating mechanism maintains container array integrity

- Includes tray-lip hold down and lead-on mechanism

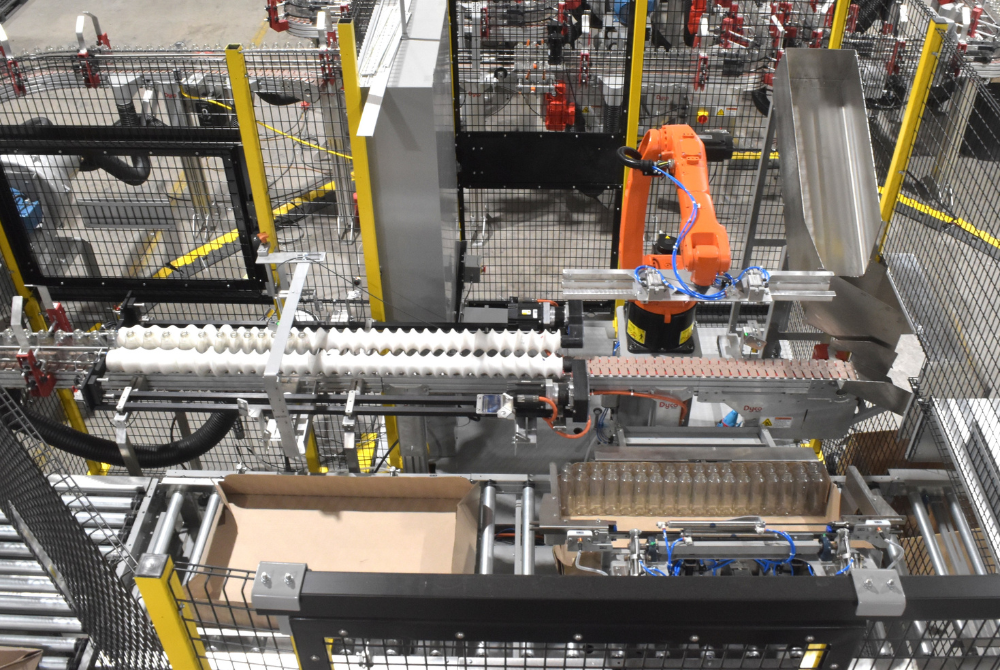

High-Speed Tray Loading

Dyco’s High-Speed Tray Loading is fully-automatic and provides efficient and fast loading of multiple bottle-and-tray combinations within a single system. Our quick change, end-of-arm tooling offers adaptability to many bottle and tray configurations and sizes.