Table Top Conveyor Products

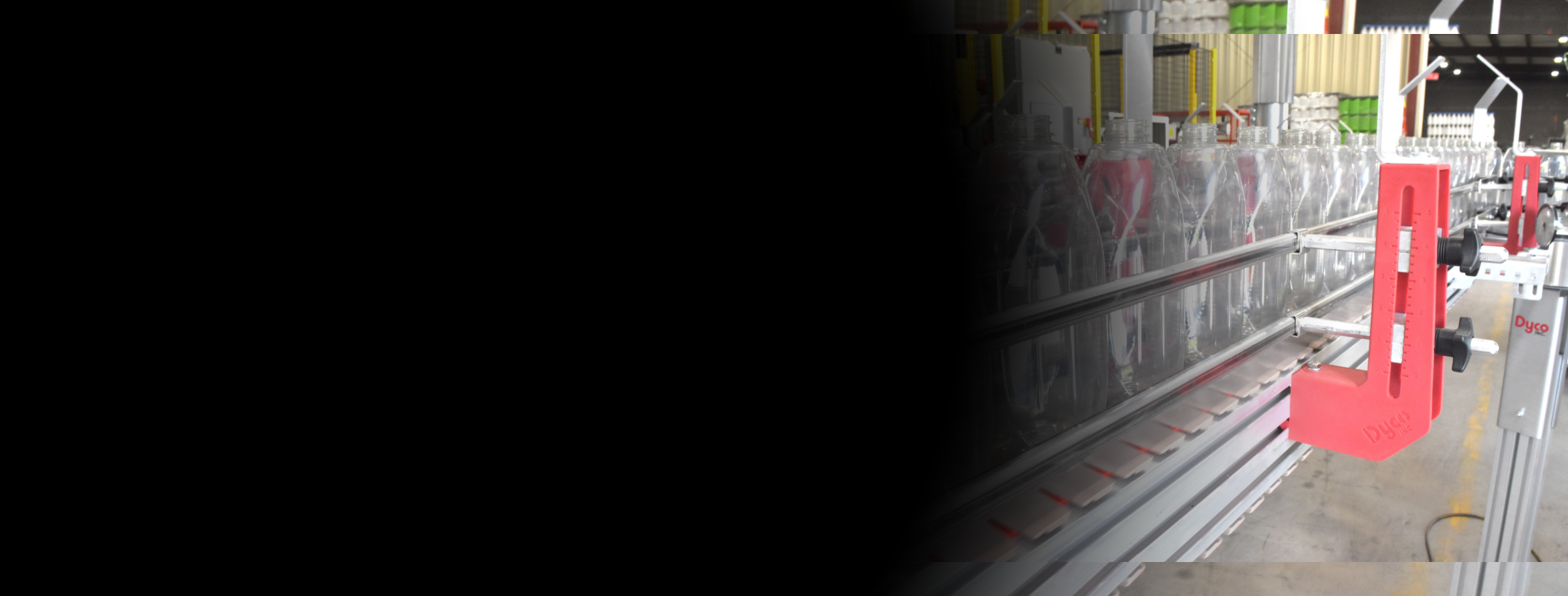

Red Line Aluminum Tabletop Conveyor

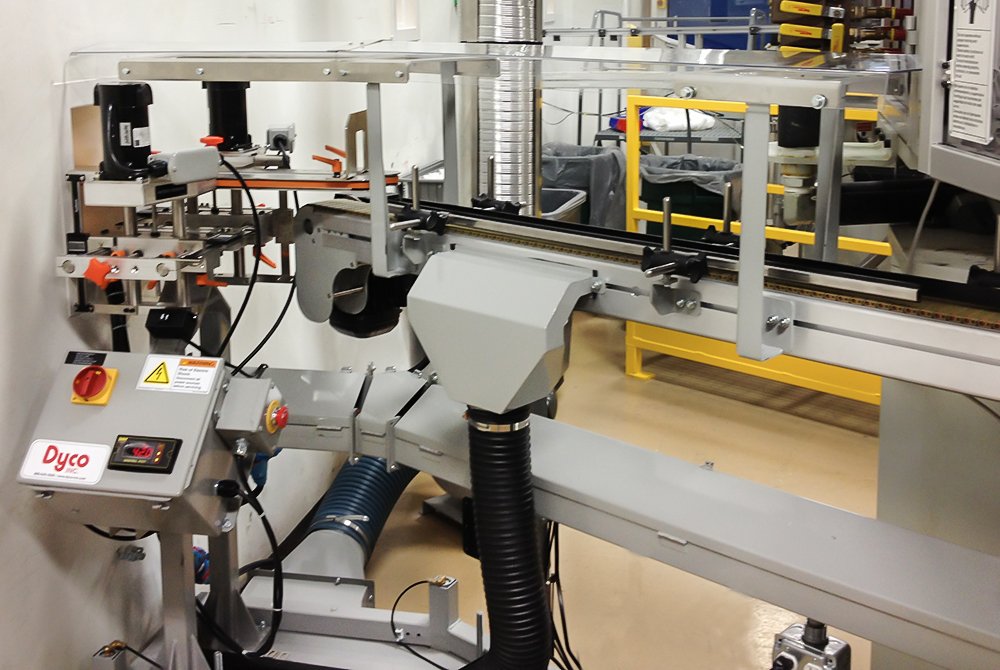

Dyco’s latest innovation in tabletop conveying systems is the Red Line Aluminum Tabletop Conveyor. Engineered for long runs and smooth, uninterrupted operation, this system eliminates chain surging and features virtually no gap between chains at drive/idler transfers. Ensuring reliable and consistent bottle movement, you’ll immediately notice the difference in your operation with the Red Line Aluminum Tabletop Conveyor

Featured in our Red Line Conveyor Catalog!

- Designed for optimum vacuum conveyor

- Available in various lengths, widths, and configurations to meet specific production needs.

- Ensures seamless product flow with minimal friction, reducing the risk of damage or downtime.

Auto-Adjust Rails

Dyco’s cutting edge Auto-Adjust Rails promise to make container changeover quick and efficient. Save valuable floor space with our patent-pending mechanism that drives both sides of the rails from the center-out, thus making our design narrower than competitor systems. Featured in our Red Line Conveyor Catalog!

- Variable radius turn rails with perfect transitions to straights with no gaps

- Automatically adjusts with the push of a button or manual crank

- Infinitely adjustable within a defined range

- Allows for placement of multiple conveyor systems closer together

Slide Gate

Dyco’s Slide Gate marks the latest innovation for our extensive line of table top conveyor. The Slide Gate allows an operator to gain access in land-locked portions of conveyor runs without stopping bottle flow. The gate provides a 36″ opening and includes a deadplate, an upline bottle brake, and sliding UHMW guiderails.

- Push button allows for easy opening and closing

- Includes gate-closed sensor for added safety measures

- Replaces the need for bulky crossover stairs on new installations

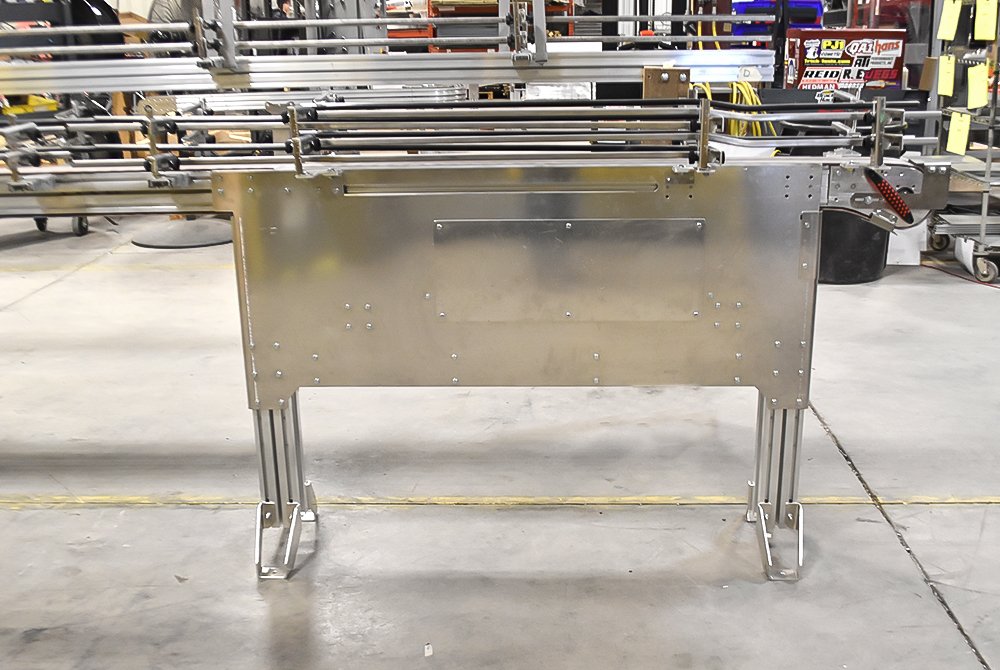

Stainless Steel Table Top Conveyor

Dyco offers both open frame and closed frame stainless steel table top conveyor, which are perfect for washdown and wet environments. Our stainless steel table top conveyor works well for lines that need to be hosed down and cleaned or for lines that could have product leaking onto the conveyor.

- Perfect for industries requiring frequent cleaning or handling of products that may leak onto the conveyor.

- Available in closed frame, open frame, or sanitary conveyor frame.

- Offered for conveyor widths of 7 ½” and up, providing an economical alternative.

Painted Steel Table Top Conveyor

For 7 1/2″ and wider widths, Dyco also offers a more cost-effective painted steel option for table top conveyor. All designs come with a variety of conveyor rail options and most are available for integrated vacuum technology.

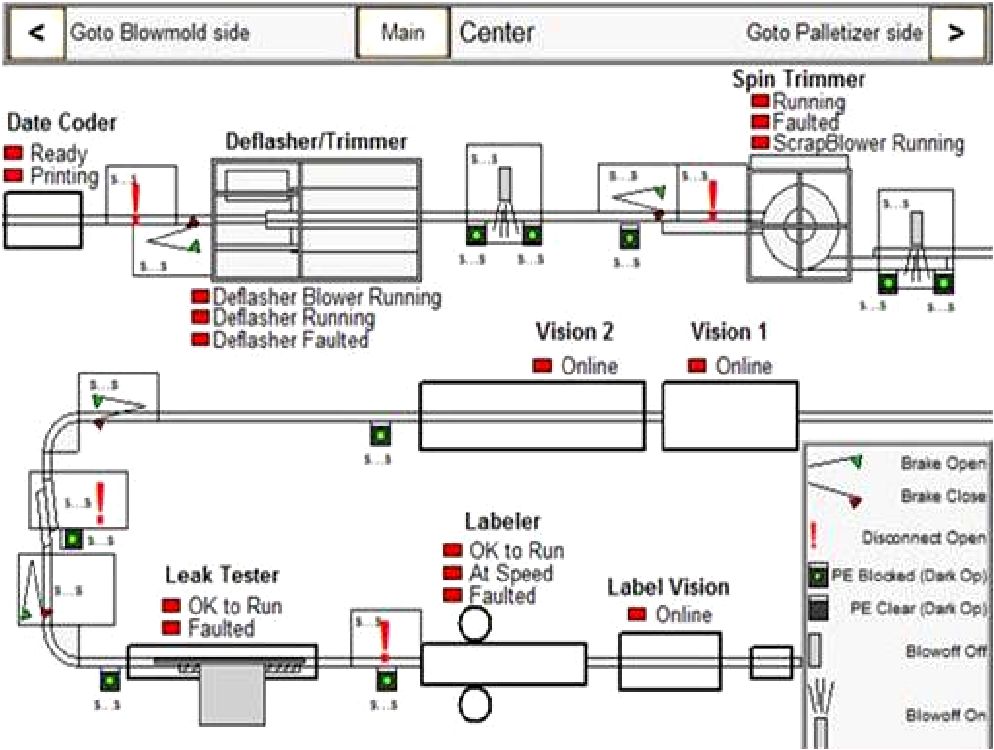

Control Systems for Table Top Conveyor

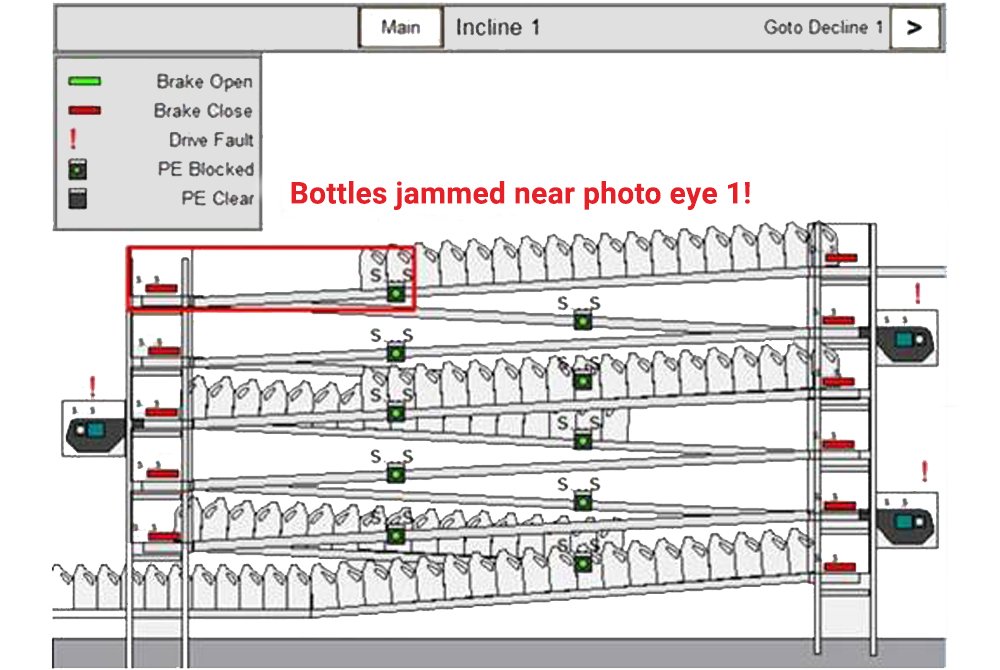

Dyco offers a full range of table top conveyor control systems, from simple, stand-alone units, to central control systems with cross-functional communication. Our expert PLC programmers will provide you with the ideal, complete turnkey solution for your application.

- Integrated control systems operate and monitor your entire conveyor system

- Touchscreen monitoring and system controls

- Fully integrated, programmable logic controls

- System schematic for training and operation

Options for all Table Top Conveyor

Pneumatically Adjustable Rails from Dyco allow a single table top conveyor to run multiple containers by allowing four different rail width settings. The settings are easily changed with just the flip of a switch, thus making them ideal for hard-to-reach overhead conveyor lines.

Dyco’s Vacuum Table Top Conveyor provides a perfect solution for unsteady containers to keep them stabilized through the conveying process. Our vacuum technology works well with Red Line, stainless steel, and painted steel table top conveyor systems.

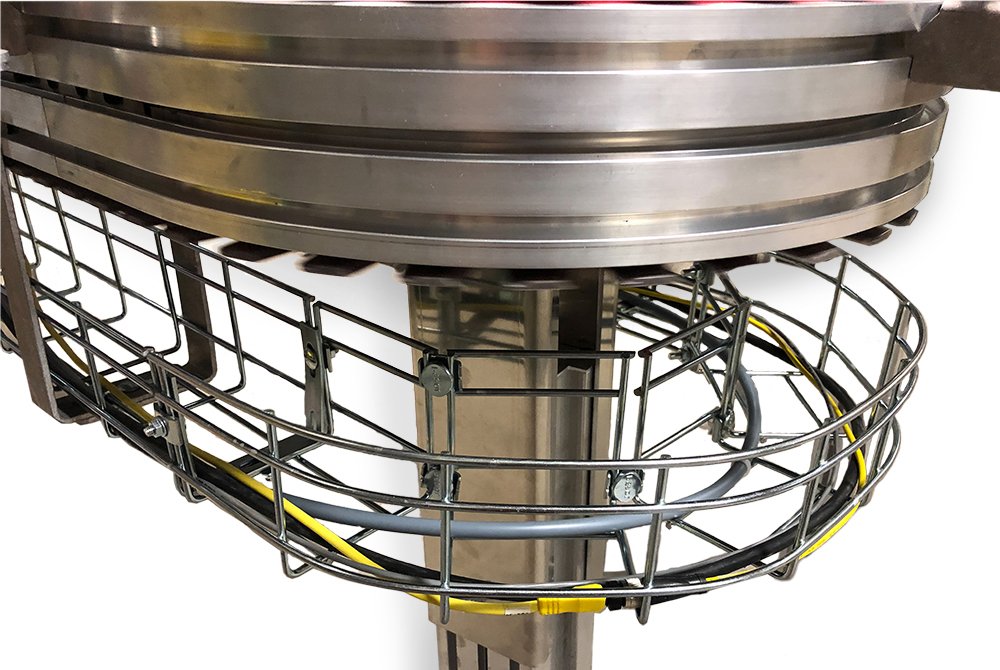

Add Wire Baskets (pictured on Red Line) to any table top conveyor for neatly holding wires, cables, and air lines. An optional divider separates high voltage and low voltage wires from each other.

Casters (pictured on Red Line) on the floor stands allow for mobility of the table top conveyor throughout the shop floor. The leveling feet, meanwhile, provides stability.

Trial-Sized Bottle Straight Running Table Top Conveyor

For bottle sizes that are too small to run on standard table top conveyor, Dyco offers a customized solution for trial-sized – and similar-sized – bottles. Our conveyor system is specifically designed to fit your container and comes available with vacuum capable, flame retardant, and hydraulic lift options.

- Lightweight drive and AC/DC options for full range of conveying possibilities

- Fully integrated programmable logic controls

Conveyor Rail Options for Table Top Conveyor

From extruded aluminum, to stainless steel backed anti-static UHMW, to beaded – Dyco offers a wide variety of rail types to allow for the perfect conveyance for your plastic bottles or containers. Ask us for the ideal rail system for your table top conveyor to ensure minimum product damage.